Laboratory

Our Blog

What is the Difference Between Analytical Balances and Precision Balances?

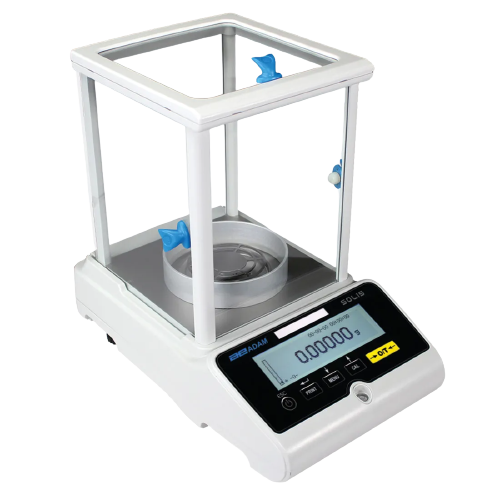

Laboratory balances come in a few different shapes and sizes, each with their own advantages and disadvantages. Since they’re highly specialized equipment, it’s important to know the distinctions between semi-micro, analytical, precision, and top-loading balances. This blog post will do just that, using our Equinox, Solis and Luna balances as examples.

For Analytical Balances, There are No 'Good Vibrations'

When you’re working with high-accuracy lab equipment like semi-micro and analytical balances, one of the first things you learn is just how sensitive they are to outside forces like vibrations, air currents and even air temperature. To help ensure the integrity of weighing results, these factors must be mitigated. In this blog post, we’ll look at how to address the effects of even the most subtle reverberations with an anti-vibration table.

What are Precision Balances?

The words precision and balance almost seem like a tautology; after all, you expect any balance you buy to be precise. In the weighing industry, precision balances are a specific category of weighing instruments that refer to the level of resolution or readability they offer. In this post, we’ll explore the functions that make precision balances different from other balances, their definition, their applications, and more.

Frequently Asked Questions

Laboratory balance is a broad term used to refer to any balance that can be used within a laboratory environment. This predominantly includes analytical and precision balances that are capable of carrying out highly precise weighing tasks, testing and research. Digital laboratory balances are readable to up to 0.01mg and are optimally used with anti-vibration tables and draught shields to keep weighing results accurate.

Research and development laboratories rely on Adam Equipment balances for weighing chemicals, powders and other samples.

- Pharmaceutical labs use analytical and precision balances for research and development, for quality control during production, and in pilot testing.

- Adam balances and moisture analysers make it simple for materials testing labs to verify construction substances, such as concrete or asphalt. Food processing and manufacturing facilities use Adam lab balances in quality assurance testing, to achieve consistent production quality and to ensure items meet standards.

- Digital balances and scales are used in forensics labs to weigh evidence seized during crime investigations.

Laboratory balances can be calibrated in two different ways: Internal or external calibration. Internal calibration uses an internal mechanism to calibrate the scale and can often be achieved with the push of a button, meaning calibration weights are not necessary. This method is faster and easier, although the capability will add to the price of your laboratory balance. External calibration involves manually calibrating your laboratory weighing balance using external calibration weights. Users place the weights onto the laboratory balance when it is calibration mode and can then establish whether the displayed weight is correct.