For use in busy industrial facilities, Adam Equipment’s AELP pallet beams can definitely be described as a workhorse. TimberHP, the first dry process wood fiber manufacturer in North America, uses in their Madison, Maine facility.

Download the PDF by clicking the link above

Using one of the planet’s most renewable resources – small diameter trees and residual wood chips left over from sustainable forestry practices – TimberHP creates wood fiber insulation products. According to the company, its toxin-free insulation is resistant to moisture, mold and fire, while reducing heating and cooling loads. Its products are competitive with traditional insulation, and are safe and easy to install, requiring neither hazmat suit nor face mask.

The company’s products line includes TimberBoard, TimberBatt and TimberFill.

TimberBoard, a carbon-negative insulation board, can be used for both exterior and interior use. It’s available with a single-ply square edge or with a tongue-and-groove edge to connect boards together.

Benefitting from the natural sound-absorbing properties of wood, TimberBatt is used for thermal cavities and acoustic insulation.

Blown-in TimberFill provides dense-pack cavity insulation for walls, floors and ceilings, and loose fill insulation for attics.

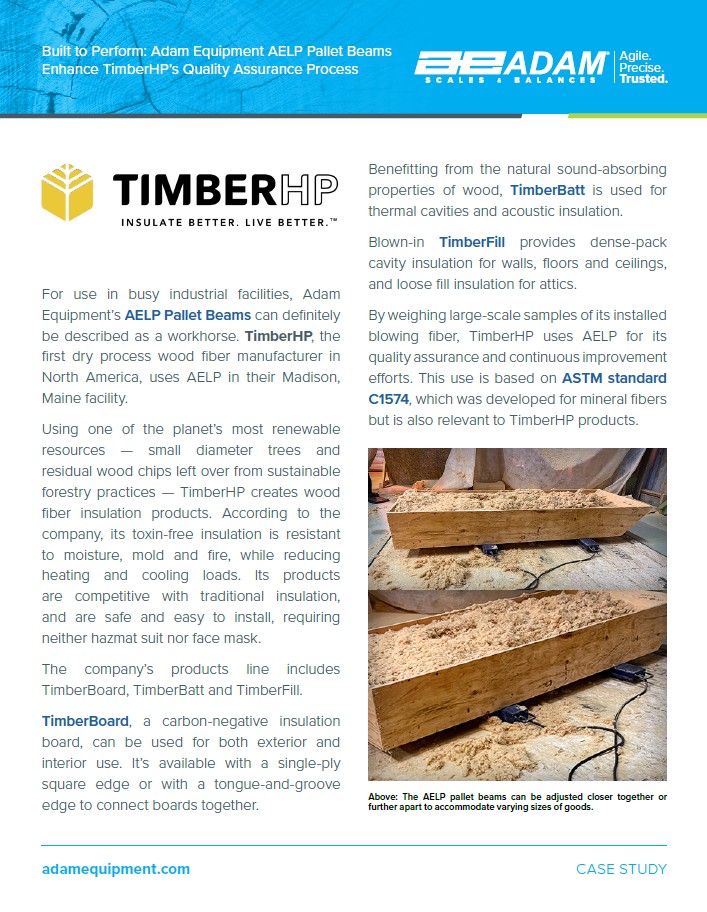

By weighing large-scale samples of its installed blowing fiber, TimberHP uses AELP for its quality assurance and continuous improvement efforts. This use is based on ASTM standard C1574, which was developed for mineral fibers but is also relevant to TimberHP products.

AELP was also used during the installation of an 80 sq. ft. attic space, which was instrumental in developing the coverage charts the company publishes on their product bags as a reference for installers.

“This larger sample size allows us to get a more accurate reading of the installed density, which helps to determine the coverage chart for attic applications,” according to Jason Todd, TimberHP’s Director of Building Science and Industry Support. “We can also weigh larger wall sections to ensure that the installed density within a cavity is self-supporting, meaning it won’t slump or sag over time.”

One of the things that make AELP so useful for TimberHP is that the pallet beams can be adjusted closer together or further apart to accommodate varying sizes of goods that need to be weighed. This includes a variety of objects, like containers or platforms.

The rugged beams – which offer capacities from 2200lb / 1000kg to 6600lb /3000kg and readabilities from 0.5lb / 0.2kg to 2lb/ 0.5kg – are built for demanding environments, making them suitable for industrial use like TimberHP. “Precision, of course, matters, but since we are an industrial facility, durability is also very important,” Todd added.

Paired with one of Adam Equipment weighing indicators (such as the and checkweighing indicators or the label-printing indicator), AELP can be customized to the user’s needs.

With their AELP, TimberHP uses an . The rugged, stainless steel AE 403 is rated IP68, which means the indicator is fully protected from particulates matter like dust and can be safely and easily washed down.

For easy reading of weighing results, the indicator is connected to AELP by a 15-ft. shielded cable and can be placed for optimal viewing. With built-in wheels and handles, AELP goes where it’s needed: the beams can easily be moved around in a warehouse, manufacturing facility or even on a job site.

Scales are part of TimberHP’s production process throughout various stages, from quality control to manufacturing.

In addition to AELP, TimberHP employs weighing scales for other uses in its manufacturing facility, including:

• Weighing material in its lab and testing stations (verifying thermal or fire resistance characteristics at the correct density)

• The weight of bags of TimberFill are monitored on the conveyor in the packaging line

• The correct ratio of refined softwood fiber to an engineered binding fiber is determined by weight when making the TimberBatt material.

In the field, installation support teams can weigh samples to ensure that the blown fiber is installed correctly.

From lab testing to packaging to in-field verification, weighing solutions like Adam Equipment’s AELP pallet beams are seamlessly integrated into TimberHP’s operations. Their versatility and durability support TimberHP’s mission to deliver safe, sustainable and high-performance insulation products.