When you have a bunch of parts to count, and it’s looking overwhelming, is it better to invest in a counting scale, or a scale with a counting function? What’s the difference, and when would you choose one over the other? This blog explains what parts counting is, the difference between counting scales and scales with a counting function, and real-world applications where you might need one or the other.

What is Parts Counting?

Parts counting is an application that allows your weighing scale to calculate the number of parts that you’ve placed on the scale. To do this, the scale requires a small sample of the parts, let’s say five or ten, so it can gather an average weight of each part. Once the scale has an average weight, you can pile on parts at random, and the scale will be able to display the correct count.

As pieces are added to the scale, it will recalculate and refine the piece weight, should the average turn out different than that provided in the sample. This is called parts counting optimisation. Of course, make sure you're not mixing different types of parts together, since the scale won't be able to determine which is which and you’ll likely have an incorrect count.

Scales with a Counting Function vs. Counting Scales

Many weighing scales offer supplemental applications such as parts counting as bonuses in addition to regular weighing. These applications are excellent for when you’re only performing parts counting occasionally, rather than every day.

For example, our is an IP68-rated waterproof scale. It offers parts counting, checkweighing, and percentage counting as additional functions. However, there are few features specific to each additional function because you would use the ABW-S primarily for regular weighing in wet or dirty environments. On the rare occasions where you do need to perform parts counting with your ABW-S, the built-in application saves you from purchasing a counting scale built for the job.

A counting scale is a scale with features that help make parts counting easier and more efficient. They’re perfect if you use parts counting in your day-to-day work. Here are some of the features that would benefit you should you purchase a counting scale:

Full Numeric Keypad

Many scales with a counting function will require you to choose between a certain number you must provide as a sample size. For example, the ABW-S asks you to place five, ten, or twenty screws on the pan so it can gain the average weight. For those less experienced with parts counting, this is a great way to guide you through the process and help you out.

Counting scales will allow you to type in whatever sample size you’d like on the full numeric keypad, which provides a simple yet meaningful way to be more convenient for those who use parts counting often. In this case, frequent fliers likely already know what a decent sample size is and will place some on the pan accordingly. This also allows you to type in the average weight you’d like to use if you happen to know it already, without weighing a sample first at all.

Specialised Buttons

A counting scale will typically offer dedicated buttons on the display that will automatically bring you to certain stages of the process. For example, on the , you can press the Sample button to enter your sample size. Likewise with the Unit Weight button, so you could type in the unit weight without a sample. Our offers a simpler button system as a non-counting scale. The same button performs multiple functions, which you press in a sequence to access parts counting.

Three Display Screens

Counting scales are convenient because they boast three different display screens. The first screen is for overall weight. The second is for the average weight per piece, and the third is the official count of parts. This helps keep all the numbers distinct in your mind and makes keeping records easier. Since regular weighing doesn’t require three screens, one will be enough for most other weighing scales, with the screen switching modes when necessary.

PLU’s

Many counting scales, like our , offer a PLU function, or "Product Look-Up." This means that if you frequently need to count ½-inch Phillips head screws, for example, you could save the unit weight for them in the scale itself, under a numeric code you assign to that part. This saves you time, since you don’t have to gather samples and unit weights more than once. To access these PLUs, there’s also a dedicated PLU button. Checkweighing and retail scales also offer PLUs, making operation quicker and more efficient overall. To learn more about PLU’s, check out this blog.

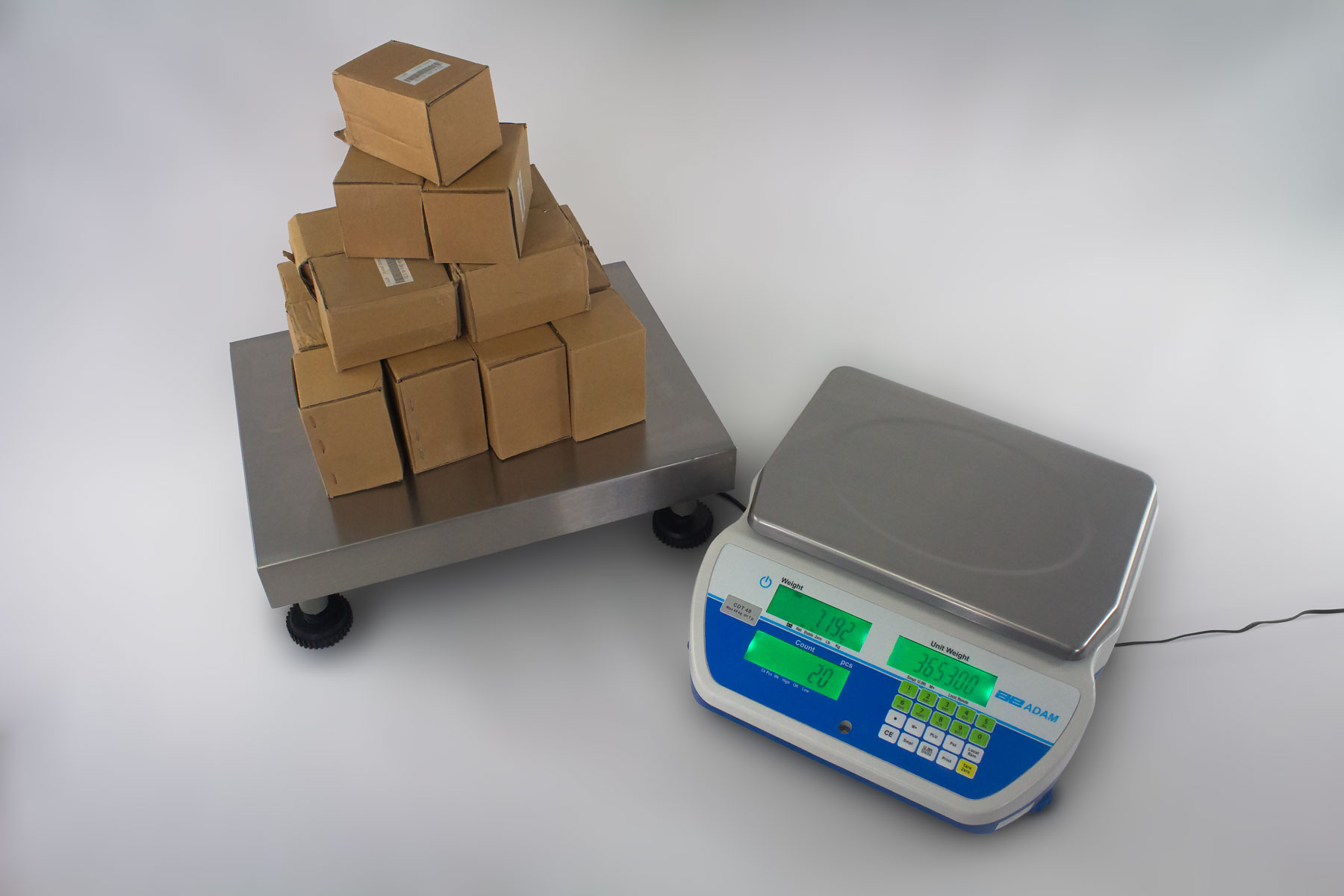

Auxiliary Platforms

Our can be connected to an auxiliary platform. The CDT may have the readability and capacity you desire most of the time, but when you require a higher capacity, there’s no need to purchase an entirely different scale. A weighing platform can be connected to the CDT via cable, providing you with the higher capacity you need.

If you’re always counting in large quantities, or with heavier items, not to worry. Our are available with capacities from 75kg to 300kg.

Real-World Applications for Counting Scales

What kind of jobs would require the use of a counting scale?

Counting Scales in Manufacturing

There are multiple stages of the manufacturing process that would require the use of a counting scale. For example, when you pack boxes or containers of items. Let’s take a box of tea bags. Each box of the same flavor and brand should have the same amount of tea bags – but counting them all manually would add precious time that could be spent packing more boxes. If you provide your counting scale with a sample of tea bags, you’ll then be able to pile on bags until you get the amount required in each box. Rinse and repeat.

Assembly lines are well-oiled machines, but sometimes human error can get in the way. For example, if one step of the process is to add four screws to four corners of an item, then there better be four screws available to complete this step. If there’s a quota of products you’re trying to complete each day, a counting scale will help you make sure that there is enough of each component to meet that goal without requiring a refill before or during the process, saving you time.

Parts Counting for Stock Taking/Inventory

In a similar vein, when it comes to the time for inventory counts at the end of the year, your counting scale will make this a breeze. Taking an accurate inventory is extremely important, as it can help you keep track of your merchandise and parts. This way, you know exactly how many you’ve used or sold, and can order more when necessary. There’s nothing worse than finding you’re out of stock of a highly requested item and may have to delay shipment.

Do you need to keep a record of how many four-count bags of 5/16-inch Zinc-plated Steel Square Nuts are stocked in your hardware shop? Instead of taking the time to count manually, let your counting scale do all the work for you. Then, when you’re done, you can store that part in the scale’s memory for recall next time you perform inventory.

Need help deciding which counting scale, or scale with a counting function, is right for you? Contact our team, we’ll be happy to help.