Without quality control, a product would never be the same twice. Scales and balances are one way to make certain that each product is consistent. This blog goes into the top three types of weighing equipment we recommend for quality control applications.

More of a visual learner? Download our complementary infographic by clicking the picture below.

1. Moisture Analysers

When manufacturing a product, there are very specific requirements on moisture content. This is because moisture impacts the product’s stability, quality and shelf life. With too much moisture, a digestive biscuit may be more chewy than crunchy, with a higher chance of growing mold. Too little moisture and toothpaste would be more like a minty chalk or powder. It would be hard to squeeze and difficult to brush with.

Moisture analysers like Adam Equipment’s play a large part in quality control. They check products like food, plastics, cosmetics and pharmaceuticals to ensure each batch maintains moisture standards.

Why Choose the PMB Moisture Analyser for Quality Control?

To determine the moisture content of a sample, you must weigh the sample. Then, heat it until dry and weigh it again. You then take the difference between the initial and end weights and use it to determine the overall moisture content. This is known as the loss-on-drying method.

A common way people perform this process is to weigh the sample on a scale, then bake it in an oven. Once dry, they weigh it again and calculate the percentage manually. This is inefficient, as it takes a long time and can be prone to human error. The PMB removes these concerns.

All-in-One Operation Reduces Errors

Adam’s PMB Moisture Analyser performs the entire process, from weighing to drying and calculating the moisture percentage, by itself. This is significantly more efficient than switching from scale to oven and back again. It also eliminates the risk of errors caused by manually miscalculating the moisture percentage.

Quick Drying Improves Efficiency

Since the surface area of the PMB’s pan is small, it’s able to dry samples quickly. This is opposed to an oven which dries slower due to a higher surface area. Drier samples like cocoa powder only take up to two minutes of drying time. Meanwhile, liquids like red wine would only take 15-20 minutes to dry. Such rapid, accurate results minimise production delays as much as possible.

Recipe Recall Saves Prep Time

After you properly prepare the sample, you can choose between the PMB’s three heat settings and four preset drying modes. The manual recommends beginning with a temperature of 100ºC, a time interval of ten seconds and a sample sized three to eight grams for initial testing, though this downloadable chart includes the settings for common samples.

Once you’ve discovered the best settings for a particular sample, you can save the “recipe” in the PMB’s memory for recall later, reducing prep time and ensuring consistency between tests. Adam’s PMB can hold up to 49 different recipes as well as the results of up to 99 tests in its memory.

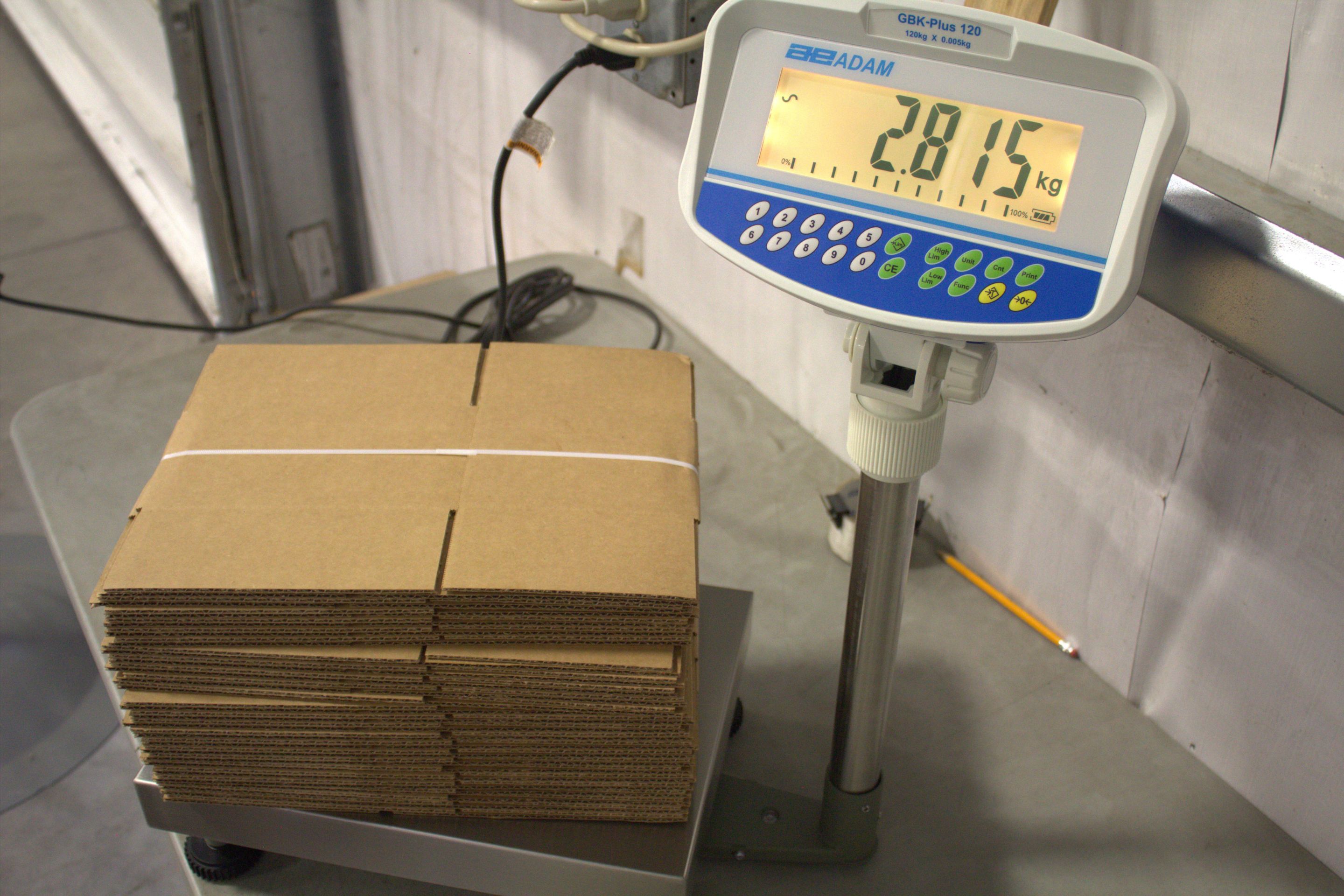

2. Checkweighing Scales

It’s illegal for a company to sell a product that weighs less than the standard weight printed on their packaging or their websites – unless the price fluxes accordingly with the weight. It’s not only because they’re paying full price to receive less than they purchased, but because a product of a different weight can imply quality issues overall.

Why Choose Checkweighing Scales for Quality Control?

Checkweighing scales ensure that each product meets the standard weight requirement without also exceeding it, which would waste materials and cost the company money.

Three Different Methods of Notification

Quality control is a fast-paced operation. If there’s a consistent problem with a product, it needs to be addressed as soon as possible so it doesn’t delay production. You can’t spend time analysing each result – which is why Adam Equipment’s new and checkweighing scales offer clear 40mm-high digits, colour-changing displays an optional audible alarm. If a product is under or over limits, you’re quickly notified through three different means that can all be understood from a distance.

Customizable Limits Ensure Product Consistency

With a full numeric keypad, the and GBK/GFK-Plus allow you to easily and fully customise your checkweighing limits, so you can get as specific as necessary. For example, if a box of pumpkin pie must be at least 140g to meet legal and quality standards but can’t exceed 142g. Entering these weights as your high and low limits gives you a speedy way of quality control.

Limit Recall Saves Time and Prevents Errors

It can be a pain to re-enter checkweighing limits every time you need them, especially if you’re quality checking the same products frequently. Adam Equipment’s GBK/GFK-Plus as well as Adam’s Cruiser CKT Checkweighing Scale allow you to store up to ten preset limits for quick recall later, including the weighing units being used. This way, you can jump straight into checkweighing instead of spending time on prep.

3. Analytical Balances

The smaller a product, the bigger the deal it is when its weight is a few ticks off standard. If a medicine capsule, for example, weighs more or less than it should, it could mean that there’s an incorrect level of medication within. This could be dangerous, as medicine is formulated with extremely precise dosages in mind.

To quality control such small samples, analytical balances are an excellent tool.

Fine Readability Assures Precision

With readabilities between 0.1mg and 0.0001g, Adam’s and Analytical Balances can detect the most minute differences in weight.

Luna Analytical balances also offer a checkweighing function, so you can set highly precise weighing limits that guarantee each small sample is correct.

Guarantee Traceability and Accurate Records

All of Adam Equipment’s moisture analysers, checkweighing scales and analytical balances offer advanced connectivity. They can be connected to printers and software like to maintain accurate records and keep track of statistics. With our communication cables, even if what we offer as standard doesn’t match your requirements, we’re able to accommodate.

Adam’s PMB and Analytical balances offer Good Laboratory Practice (GLP) standard printouts, with spots for date, time and other information that make them easy to identify and replicate. Adam checkweighing scale’s printouts are compliant with Good Manufacturing Practice (GMP) standards, for the same reason.

Help guarantee that each quality control check means something with consistent records and evidence to back up your findings. If there’s a discrepancy, it may be a fluke manufacturing error, or it could be a pattern that needs to be resolved. Make your scales and balances work for you!

Wondering which quality control scale is best for your application? Contact the Adam team – we’ll be happy to help.